Heat press transfer comes in numerous paper types to suit the imprint method used, and the product the imprint is transferred to. Heat transfer paper is a special kind of paper used to make custom images. It was first invented for making patterns or graphics to be transferred to special items. Traditional heat transfers are screen printed, but modern transfers can be printed by inkjets and laser printers using special papers. The basic function of all heat transfer papers is to "transfer" the printed image onto an item by use of heat and pressure.

Such as small items like plastics, toys, packages, clothes, aprons, mouse pads and jigsaw puzzles. It can also used for large sized items such as construction materials and electric appliance.

Inkjet Printed Transfer Papers

Inkjet transfer papers are printed with special inkjet "sublimation"

inks. Sublimation transfers the ink from the paper to the item when ink

is heated into a gaseous state. Sublimation transfers produce a very

soft imprint feel on fabric, but are also used to imprint

specially-coated hard goods such as mugs, and other decorative,

promotional, and utility items. Both warm and cold-peel sublimation

methods can be used depending on the item being imprinted. Sublimation

transfers can only be applied to polyester-coated surfaces, or garments

with a high polyester content. Since the ink is transferred as a gas,

the imprint penetrates the polyester much like a dye, and is quite

permanent.

Heat Transfer Paper Used for Garment

As long as the garment industry is concerned, it makes custom images onto T-shirts, dresses, pants and many other kinds of clothes much more fashionable and richer in styles.

As long as the garment industry is concerned, it makes custom images onto T-shirts, dresses, pants and many other kinds of clothes much more fashionable and richer in styles.

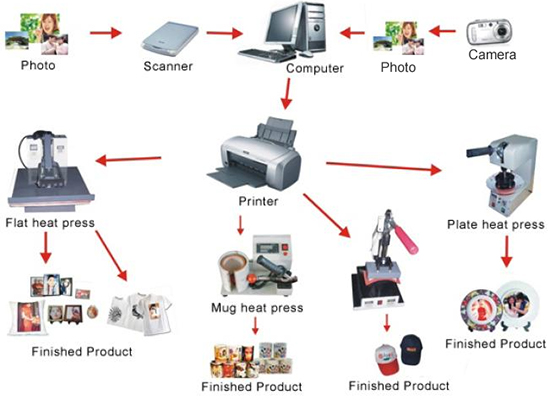

People design custom images with various colors and apply them onto

transfer paper to make the image better in looking. A heat press can

then transfer the image onto clothing, canvas, or other surface.

Transfer paper is generally used in creating iron-ons. Except for the

ordinary pictures, hotfix rhinestone motifs can be used for garment

decoration using heat transfer paper.

Laser Printed Transfer Papers

Laser printed transfers can also be printed with standard inkjet

printers, and contain a special protective coating that is transferred

along with the imprint. This type of transfer is used mainly for cloth

goods, and produces a bright imprint with a transparent, filmy coating.

Transfer Paper Tips

Transfer paper, like any

paper, should be kept in humidity-controlled environments when not in

use. Humid or very dry conditions can cause paper to swell or shrink,

affecting print quality and application performance. Purchase transfer

paper that suits your particular or preferred printing method, and test

all papers for suitability before using for customer jobs.